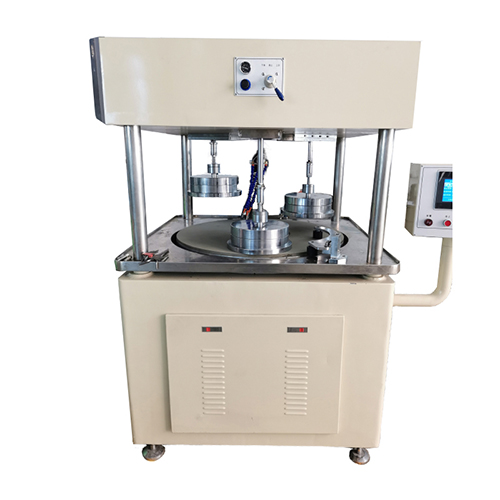

I-Wafer Grinder isetyenziswa kumzi-mveliso we-semiconductor, onokukhawuleza ii-wafers ezibhityileyo, kwaye ingasetyenziselwa ukwenza ezinye izinto ezincinci ezibhityileyo. Ezinje ngesilicon wafers, silicon carbide, sapphire, gallium arsenide, gallium nitride, ceramics, lithium tantalate, lithium niobate, indium sulfide, barium titanate, molding compound, chips, njl.

Izinto eziluncedo zesigrisi esisiqingqi esiveliswe nguTengyu:

1). Ukuphumelela okuphezulu, isantya esiphezulu sevili lokugaya sinokufikelela kwi-3000rpm;

2). Ubukhulu be-2.6-intshi ye-wafer ingaba yi-60um;

3). Ubunzima bunokulawulwa ngokufanelekileyo, kwaye ukunyamezela kobunzima kunokulawulwa ngaphakathi kwe-± 0.005;

4). I-Flatness kunye ne-parallelism iphezulu kakhulu kunezigayi eziqhelekileyo;

5). Inkqubo ilawulwa ngokuchanekileyo kwaye ukusebenza kulula.

6). I-adsorption ye-vacuum, imveliso igxininisekile kwaye akukho lula ukuphulwa.

I-Wafer grinder yahlulwe yaba ziindidi ezimbini: i-semi-automatic kunye ne-automatic ngokupheleleyo. Phakathi kwazo, kukho iimodeli ezininzi ze-semi-automatic, kubandakanywa imodeli esisiseko, imodeli ye-spindle ejikelezayo emoyeni, iimodeli ze-axis ezimbini, kunye neemodeli ze-axis enye, nganye inemisebenzi eyahlukeneyo kunye nokuchaneka. Ukuba uyayifuna, nceda uqhagamshelane nenkonzo yethu yabathengi ngokweenkcukacha ukuze uqinisekise eyona modeli ifanelekileyo kuwe.

Igrinder ye-wafer eveliswe nguTengyu ibekwe kwimarike iminyaka emininzi. Ngenxa yokusetyenziswa kwayo okubanzi, iimveliso ezibhityisiweyo zichanekile, ubomi benkonzo ende kunye nesantya esisezantsi sokungaphumeleli, kwaye ziphumelele indumiso ngamxhelo mnye kubathengi.

Singumvelisi we-wafer grinder e-China, kwaye i-wafer grinders yethu ithunyelwa eMalaysia, eSingapore, e-Indonesia, eThailand, eMzantsi Korea, eTaiwan, eRashiya nakwamanye amazwe.

English

English  Esperanto

Esperanto  Беларус

Беларус  Shqiptar

Shqiptar  lugha ya Kiswahili

lugha ya Kiswahili  Bosanski

Bosanski  ជនជាតិខ្មែរ

ជនជាតិខ្មែរ  Кыргыз тили

Кыргыз тили  Монгол хэл

Монгол хэл  IsiXhosa

IsiXhosa  Точик

Точик  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  اردو

اردو  Ελληνικά

Ελληνικά  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақ

Қазақ  Euskal

Euskal  Azərbaycan

Azərbaycan  slovenský

slovenský  Српски

Српски  Română

Română