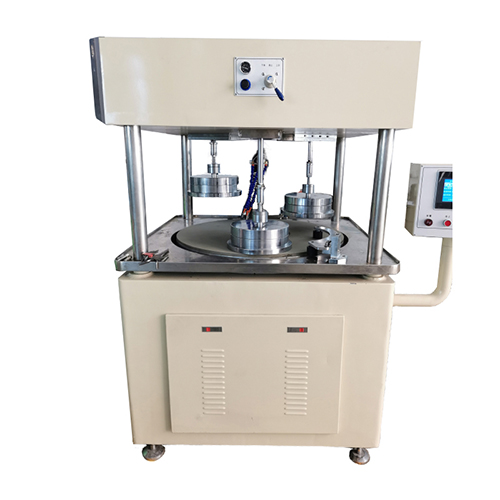

I-Wafer & semiconductor polishing slurry yi-colloidal silica slurry ephuhliswe ngokukodwa ukugudisa iiseramikhi, kunye ne-electronic substrates ezifana ne-lithium tantalate (LiTaO3), lithium niobate (LiNbO3), kunye ne'Glass Photomask, Ferrite Ceramics, Ni-P Disk, Crystal, PZT Ceramics. , iBarium Titanate Ceramics, iSilicon engenanto, iAlumina Ceramics, iCaF2, iBare Silicon Wafer Rework, iiCeramics zeSiC, iSapphire, iiSubstrates zeElectronic, iiCeramics, iCrystal. Ngokufana okugqwesileyo kwamasuntswana kunye nokusabalalisa, ihambisa izinga eliphezulu lokususa kunye nokupolisha okungenamonakalo.

English

English  Esperanto

Esperanto  Беларус

Беларус  Shqiptar

Shqiptar  lugha ya Kiswahili

lugha ya Kiswahili  Bosanski

Bosanski  ជនជាតិខ្មែរ

ជនជាតិខ្មែរ  Кыргыз тили

Кыргыз тили  Монгол хэл

Монгол хэл  IsiXhosa

IsiXhosa  Точик

Точик  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  اردو

اردو  Ελληνικά

Ελληνικά  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақ

Қазақ  Euskal

Euskal  Azərbaycan

Azərbaycan  slovenský

slovenský  Српски

Српски  Română

Română