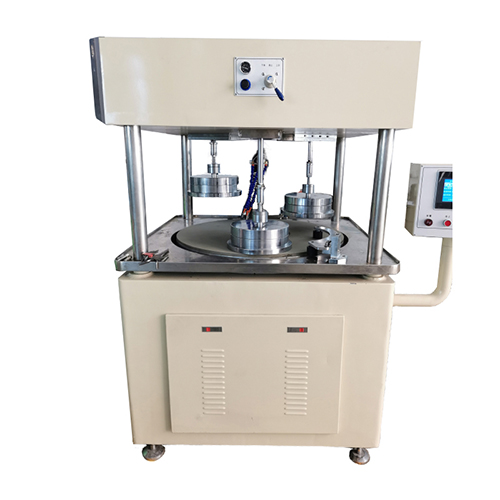

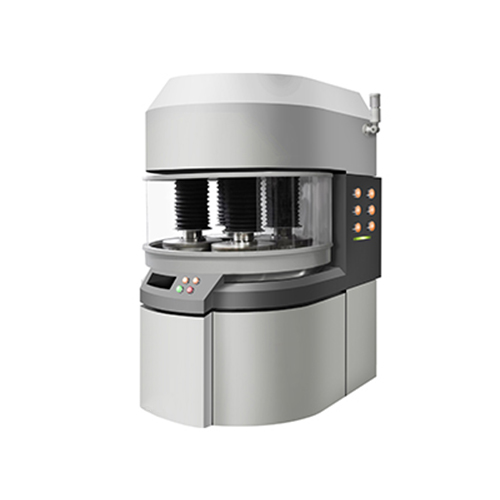

Umatshini wokutshiza luhlobo lwezixhobo zokuphucula ukutyeba komphezulu kunye noburhabaxa beemveliso. Yahlulahlulwe yaba ngumatshini wokuqhotsa kwicala elinye kunye noomatshini bokuLapha ngobuso obuBini. Umatshini wokuhlamba wecala elinye unokugaya kuphela icala elinye, ngelixa i-Dual Face Lapping Machine inokugaya amacala amabini ngexesha elinye. Inefuthe elihle lokusila kwintsimbi engenanto, i-tungsten steel, i-carbide enesamente, i-zinc alloy, i-aluminium alloy, i-alloy yobushushu obuphezulu, iglasi yokukhanya, i-ceramics, i-silicon wafer, i-silicon carbide, i-quartz kunye nezinye izinto.

I-Tengyu ngumenzi womatshini wokurhola ogxile kwi-R&D kunye nemveliso. Ngumvelisi okumgangatho ophezulu e-China, kunye neworkshop yemveliso ye-6000 square metres, indawo yeofisi ye-2000 square metres, iqela elinamandla lobugcisa kunye nenkqubo yenkonzo egqibeleleyo emva kokuthengisa.

Umatshini wokulaphukisa oveliswe nguTengyu unezi zibonelelo zilandelayo:

1). Ngesixhobo sokulungisa ipleyiti ezenzekelayo, inokuqinisekisa ukuphakama okuphezulu kwepleyiti, kwaye inokuqinisekisa ukuba i-workpiece ine-flatness ephezulu emva kokugaya;

2). Ingasetyenziselwa ukugaya okanye ukupolisha, kwaye uburhabaxa emva kokupolisha bunokufikelela kwinqanaba le-nanometer.

3). Sisixhobo semi-automatic. Ngaphandle kokulayisha ngesandla kunye nokukhulula, eminye imisebenzi inokwenziwa ngokuzenzekelayo ngokweeparitha ezibekwe kwipaneli yokulawula. Oku konga abasebenzi kwaye kuphucula ukusebenza kakuhle.

4). Umatshini wokulahla othengiswa nguTengyu uxhotyiswe ngokupheleleyo, kulula ukusebenza, kwaye unokubonelela ngemfundiso yevidiyo.

5). Zonke izixhobo kunye nezinto ezisetyenziswayo zinokuveliswa nguTengyu, kwaye zibonelelwa kwiiseti ezipheleleyo, ngoko akukho mfuneko yokufumana abanye ababoneleli abafanelekileyo.

English

English  Esperanto

Esperanto  Беларус

Беларус  Shqiptar

Shqiptar  lugha ya Kiswahili

lugha ya Kiswahili  Bosanski

Bosanski  ជនជាតិខ្មែរ

ជនជាតិខ្មែរ  Кыргыз тили

Кыргыз тили  Монгол хэл

Монгол хэл  IsiXhosa

IsiXhosa  Точик

Точик  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  اردو

اردو  Ελληνικά

Ελληνικά  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақ

Қазақ  Euskal

Euskal  Azərbaycan

Azərbaycan  slovenský

slovenský  Српски

Српски  Română

Română